Scroll down to continue

With the prospect of VR driving the metaverse, and with 4IR and digitalisation in mining all the vogue, practical examples of VR for mining are still few

and far between…

Well, with one exception…

Working closely with top experts in mining methods, rock engineering and safety, sts3D has racked up a track record of immersive learning simulations in the

high-risk mining and metal industries. This has recently culminated in several tactile VR training solutions – VR with a sense of touch.

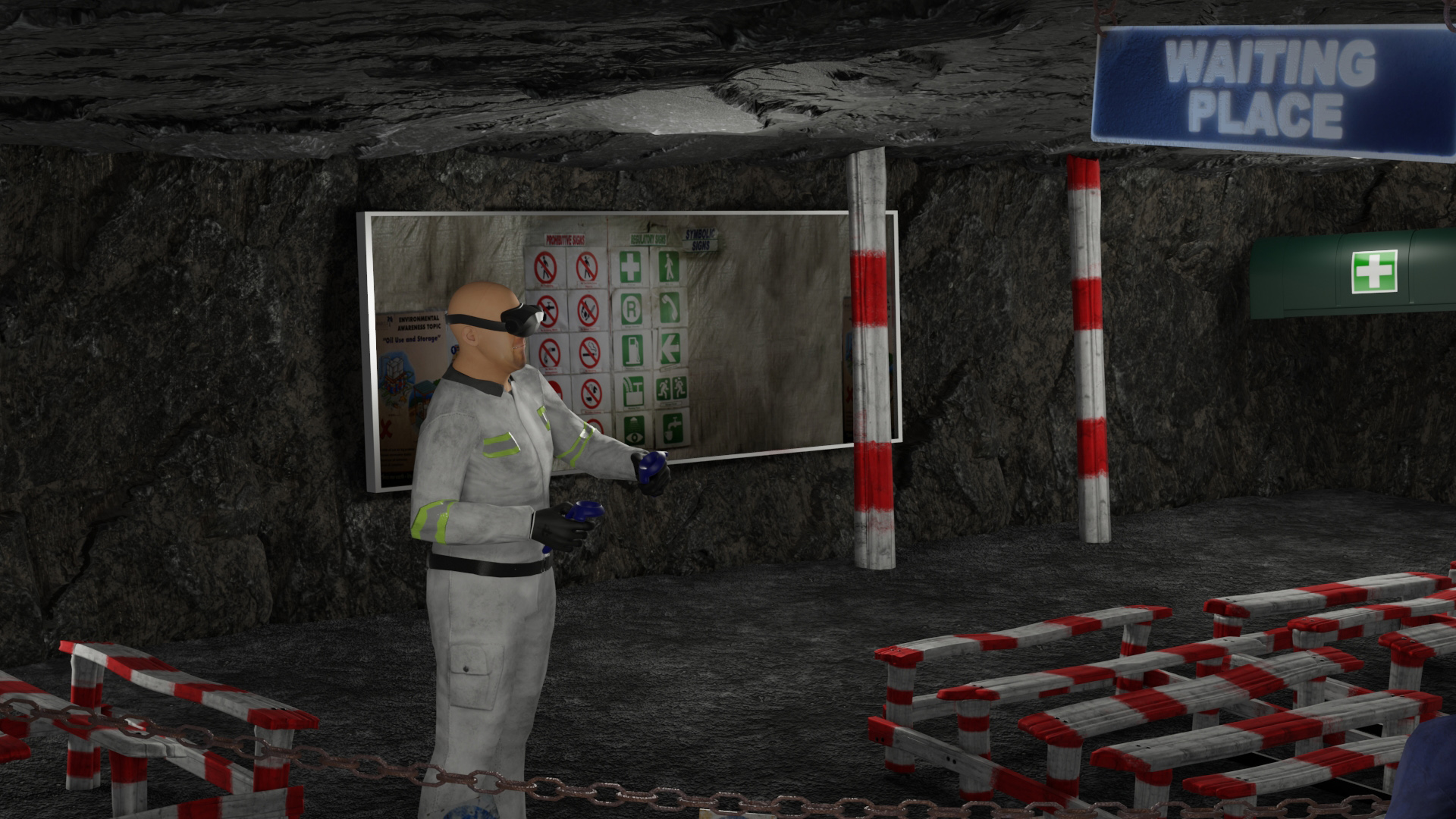

With the latest VR headsets providing an uncanny sense of realism, of 'being there', immersive learning solutions are the closest to 'real',

to 'on-the-job' training one can get. These sts3D tactile VR simulators provide practical 'learn-by-doing' – rapidly imparting psychomotor

skills such as handling vehicle controls, advanced remote-controlled machinery, or dealing with complex bolting, support installation and drilling protocols deep

underground.

“35% production improvement within 90 days – mainly due to us training Shift Bosses and Miners on Marking and Blasting in the sts3D VR

Stope.”

“The VR used in the 'Expert Miner' programme is super realistic – the best training experience ever! We now train 4 times quicker than before.”

“We are now deploying a portable VR drill rig developed by our strategic technology partner, sts3D. We now easily

transport this ground-breaking training tool in a purpose-designed trailer to wherever our mine clients would like to have it deployed – even underground.

This provides us as specialised mechanised training provider with a massive competitive advantage.”

We design our training solutions to achieve as much immersive learning as possible – combining

This combination produces immersive learning – with a sense of 'presence' and a level of bodily interaction and mental engagement ideal

for 'learn-by-doing'. When you interact with the virtual world, you make decisions just as you would in the physical world, activating the same neural

pathways in the brain. And when you practice with Virtual Reality, our training software helps to improve real-world performance as measured through assessment

data and client feedback.

Make the learning content, media and digital training tools emotionally engaging, easy to understand, easy to use and easy to apply.

Provide a meaningful context for training – with stories that resonate with the working experience and aspirations of the learners.

We show the causes-and-consequences encountered while operating in mining conditions – simulating the interaction between people, equipment and hazards

in life-like mining environments. But we also dig deeper – showing the motivational biases and dilemmas facing workers when making decisions in tough

conditions.

Immersive learning is all about 'experiential learning'. With tactile VR one 'learns by doing' – mastering psychomotor skills by building

muscle memory. Our simulations also promote pattern recognition and analytical skills, while frequent repetition and progressively more complex problem-solving and

assessment, enhance performance fluency and the self-confidence of learners.

With VR we create a sense of presence, placing the learner in a life-like situation which creates emotional responses.

Our highly realistic immersive virtual interaction activate the same neural pathways in the brain as a real-world, working environment.

Our tactile VR incorporates full-body, physical controls. To operate these controls, the user needs to use various senses and muscles. This, in turn, increases learner engagement and retention.

With VR simulations, learners make decisions like in the real world, with real-time feedback that directly contribute to accumulated experience.

In VR, the muscle movement and mental engagement help the brain build the right connections to solve problems and master psychomotor skills.

We use a step-by-step job instruction method to explain the WHAT, HOW, and WHY of operating procedures, in sequence, using simple words, short sentences, and active voice.

With VR headsets, on-demand learning becomes easy, while frequent repetition and multiple training variations help learners to achieve fluent performance.

Finally, with simulation the exposure of learners to increasingly complex challenges - such as successive hazards and cumulative critical errors - enhances knowledge transfer and long-term retention.

People are 20x more likely to remember facts when listening to a story. Why? Storytelling releases cortisol and oxytocin. Cortisol improves memory; oxytocin produces empathy. Likewise, narration activates parts in the brain - prompting listeners to turn the story into their own idea and experience. This establishes connection, sense and meaning - and satisfies the yearning of the brain to look for the cause-and-effect relationship of something it has experienced previously.

Neuroscience indicates that emotional responses - stress, surprise and accomplishment - make training more memorable. That's why we use the Danger, Importance, Positive, Interesting (DIPI) sequence for safety, and the Attention, Relevance, Confidence and Satisfaction (ARCS) sequence for experiential learning.

Hazard identification and decision-making integrate learning when the brain releases dopamine less than a second after a correct response is made. This makes learning stick.

We use form, colour, depth, and motion to capture attention and use icons to simplify messages and link the real world with the virtual environment.

Research indicates that training based on simulation games provides much better retention than instructional methods - with an improvement of 20% in self-efficacy of learners.

Our training is based on the 4 tenets of safety: relentlessly identify hazards; positively reinforce standards; conduct independent checks; and learn from errors and incidents.

We promote critical learning - presenting safety as an integral part of every operation, with a focus on root cause analysis, near misses, leading indicators, and reflective safety conversations.

Our simulations shorten the learning cycle - with motion tracking we capture where and how trainees pay attention - head movement, eye tracking, interactions, and clicks; while instant visual assessments provide learners with accurate feedback to correct or confirm their responses.

Based on our experience in developing a range of SafeWork programmes for Glencore; our adoption of instructional design best practices gleaned from the Lowell Institute for Mineral Resources at Arizona University and our pioneering range of VR and gaming applications, sts3D works as strategic partner with the Murray and Roberts Training Academy. Together with MRTA, one of the prime mining training providers in southern Africa, we are developing a comprehensive suite of digital training applications for mechanised mining.

Working with academic institutions such as the Mining Engineering departments of the universities of Johannesburg, Pretoria and Unisa, as well as the Mandela Mining Precinct on digitalisation in mining, we are uniquely positioned to share these strategic insights with clients in the mining industry.

We have considerable engineering and robotics expertise and a well-equipped workshop. This enables us to manufacture, source and tailor VR technology.

This includes the manufacturing of equipment simulators, motion platforms, projection frames and interactive touch screens; as well as the sourcing of

headsets, tracking sensors, haptic gloves and augmented reality wearables.

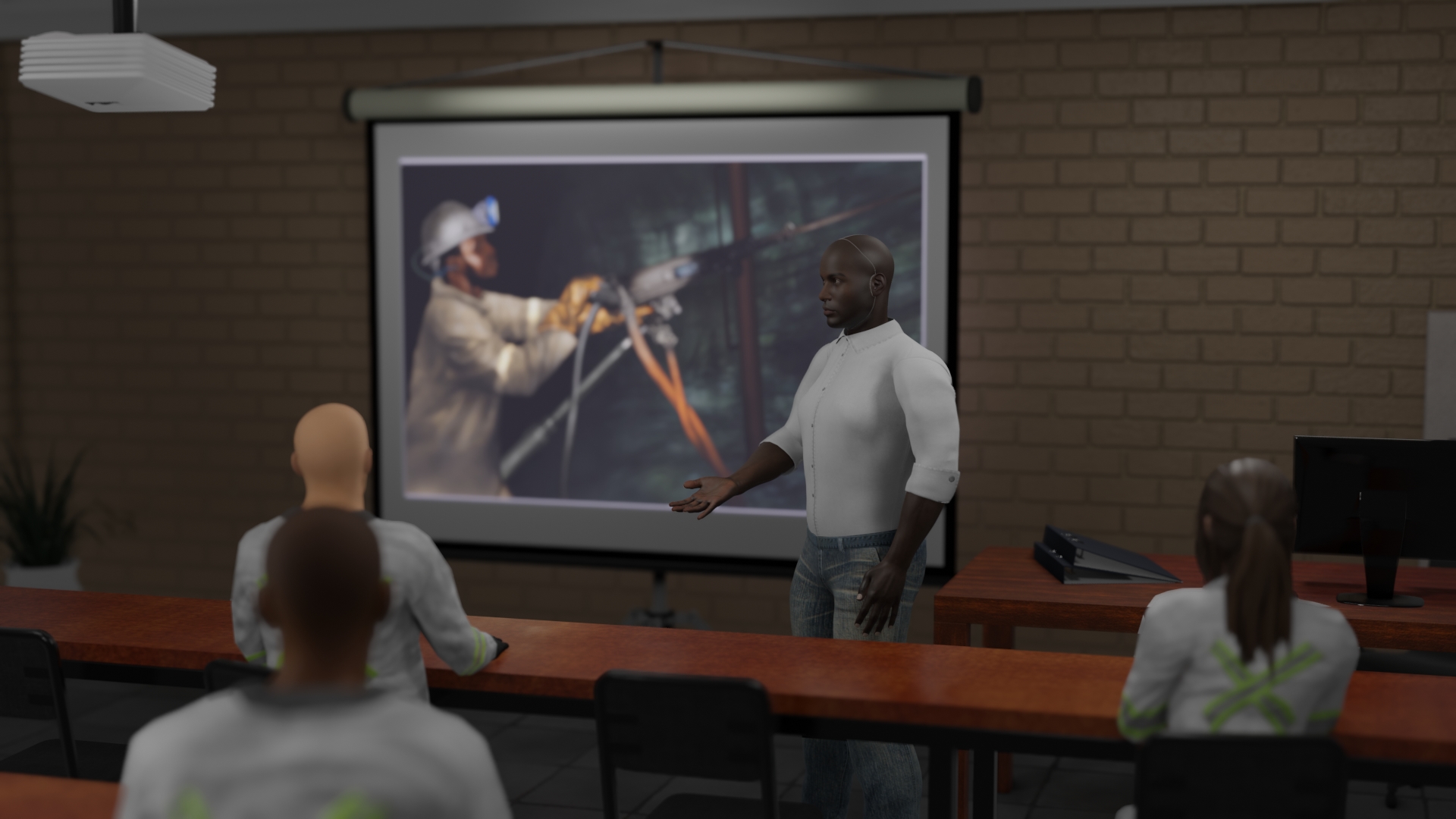

Having developed the 360 VR Centre for Mine Design at the Mining Engineering department of the University of Pretoria, the multi projector VR Stope and CUBE for

AngloAmerican, the underground VR Wall for Thorncliffe mine, sts3D has considerable expertise in the design of VR Learning Centres. Coupled with extensive

experience in operating engineering training centres, the team at sts3D understands the importance of designing learner-centred, and not instruction centred,

training delivery. We combine the learner-centred focus with the deployment of visual training techniques; peer group participation and parallel self-learning

exercises to optimise flow and eliminate waste from the training process; and use movement, space, and equipment configuration to optimise shared learning.

sts3D has delivered computer-based training facilitation services to the mining industry since 2005 and has developed comprehensive 'train-the trainer' instructional material for the training of digital trainers.

To enable clients to deploy immersive learning, we have develped an Xtended Reality platform.

The sts3D XRS is a content and learning management platform that connects digital technology enablers such as tactile simulators, projected VR solutions, and game-based e-learning tools.

The sts3D XRS offers learning, content, and contractor management modules, as well as clicker integration for group training, evaluation, and

mass opinion polls - interfacing seamlessly with client ERP and LMS platforms.

A major feature of the sts3D XRS is its content building module. This feature makes for fast and flexible content management, enabling clients to:

Building their own content - using presentations, documents, plans, pictures and videos; q's and a's.

Create and edit scenes and lessons as well as configure curricula linked to unit standards.

Apply version control over created content.

The contractor management module digitalizes the onboarding process for contractors and visitors, while achieving legal and contractual compliance of contractors by:

Scope of work delimitation.

Registration and submission, verification and authorisation of documents.

The registration, recording and update of resources such as personnel, competency certification, vehicles, tools, equipment and chemicals.

We have teams of professionally trained script writers, filmmakers, graphic designers, animators, modellers, gaming and software engineers who take pride in their creative abilities to develop innovative solutions for our clients. Our developers regularly visit our client mining sites, and have built up an impressive body of mining knowledge, enabling us to quickly deliver pinpointed products.

We specialise in learning solutions for rock engineering, geological conditions and strata control. Our product range covers real-time interactive 3D

presentations of geological conditions and rock stresses; support installation and strata control methods; and all aspects of TARP 'fall of ground' risk

management – having developed TARP programmes for more than 20 clients.

Our TARP training presents entry examination protocols in VR mines; the identification of geological hazards in 3D animated clips; orientation videos

explaining TARP and strata control protocols, 'falls of ground' incidents; and conversations about safety; as well as 2D mobile games, posters and booklets

to support the training.

We've been involved in simulating incidents since 2005 – completing more than 180, spanning incidents on all the continents. More importantly, we've developed a very robust process to do so quickly, and with clear, concise, and compelling, messages.

In mining, despite significant improvements in the reduction of fatalities, learning from incidents to prevent repeats is still a burning question.

To prevent repeat incidents, we need to learn in a different way. Incident reports and LFI alerts simply don't do it. They are often too wordy, too complicated and too imposing - one-way messages providing no opportunity for users to reflect and learn lessons which apply to their own personal circumstances.

Even if you find an LFI alert fascinating, you'll forget much of it in a few days.

People recall stories, anecdotes, and shared experiences better than details.

Reading an LFI alert isn't enough. People must make up their own minds - decide for themselves what an incident means regarding their own work situation; personally consider what could go wrong to hurt them before they change their behaviour.

The purpose with an IRS is to provide a factual and strictly sequential account to get all the execs and managers on the same page and to foster a shared understanding of what went wrong - sequence of events, cause and major contributing factors.

These simulations assist in creating a greater appreciation by executives for the constraints faced by managers on the mines, and the difficulty in implementing corporate safety directives in the absence of adequate capital allocation, technology and leadership commitment.

LFIs are designed to convey lessons learned, mostly to supervisors and the general work force. We link incidents with common everyday deviations - taking shortcuts; entering danger zones; over-riding safety devices; 'looking the other way' and failure to report near misses; and the poor use of supervisory tools such as SOPs, JSAs and PTOs.

We use a storytelling approach with strong emotional content - language. Metaphors and graphic sketches - to convey the importance of adhering to safety protocols and life-saving behaviours to help get everyone home safely after every shift.

To promote reflective learning, we supplement these lessons with personal anecdotes exploring dilemmas such as production vs safety; and with assessment questions which test user understanding of how to apply preventative measures.

We have a collection of more than 25 occupational health, hygiene and safety protocols for mines, smelters and plants, supplemented with more than 500 scenes used to assess related hazards in an interactive manner.

We use our expertise in Lean Management to develop productivity solutions in mining – illustrating improvement techniques, work methods and optimised flow using simulations games for mine cycles, shift planning, ventilation, traffic management, emergency evacuation and the elimination of wastes in operational processes.

We model leadership behaviour to coach supervisors how to use management tools – pre-shift meetings, PDCA, SLAM, JSA and PTOs – to promote safety, teamworking and problem-solving.

Let us help you develop exciting induction programmes for visitors and employees – even using VR for virtual mine, smelter or plant tours. Alternatively, use our XRS content library to

develop your own improved onboarding programme.

Make your induction available anytime, anywhere with our web-based XRS – enable visitors and new employees to complete induction before they even reach your worksite.

We follow a structured product development process, based on frequent personal engagement with our clients – seeing them as the expert 'co-creators' of 'their products'.

Our story starts in 2005, when the then CEO of AngloAmerican Platinum challenged the industry to find better ways of training mineworkers to prevent falls of ground

fatalities. In response, we started using digital technology to simulate geological hazards in underground mining. Applying a combination of art, science and

technology, we have a clear ambition – 'to help make mining safer with immersive learning solutions'. This means using VR and digital technology to reinvent

training to produce 'solutions with impact' - solutions that impact the cognitive, affective and psychomotor domains of learning in an interactive, emotionally

engaging, and user-friendly manner.

![]()

Our aim is to make life-long clients, and we strive to assist clients to become digital champions in the mining industry. To achieve this, we guide and nurture our

70 employees to serve clients with a sense of stewardship and pride in everything we do.

Wilhelm has 40 years of experience in the mining and metals industries - at operational as well as corporate level. His expertise includes human resources, productivity improvement, training and industrial relations.

Never gonna give you up. © Designed and created by Ye_Olde_Pugselot . All rights held by sts3D and Ye_Olde_Pugselot. Never gonna let you down.